Table of Contents

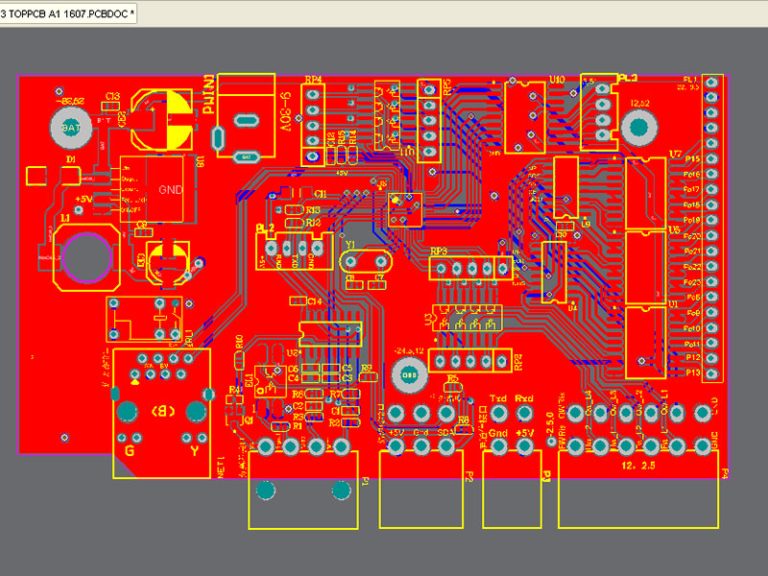

ToggleThe printed circuit board, or PCB, is an important electronic component that serves as a support for electronic components as well as a source of electronic components and electrical connections. It’s also known as a “printed” circuit plate because it’s manufactured using electronic printing. A PCB, or printed circuit board, is a narrow board that contains integrated circuits and other electrical components.

Flexible PCB boards (flexible boards), rigid PCB boards, rigid-flex PCB boards (rigid-flex boards), and other types of PCB boards are available depending on the material. Single-sided, double-sided, and multi-layered boards are classified according to the number of circuit layers. Multi-layer boards typically have 3-6 layers, while complex multi-layer boards can have up to ten layers.

Classification of PCB produced by PCB board manufacturers.

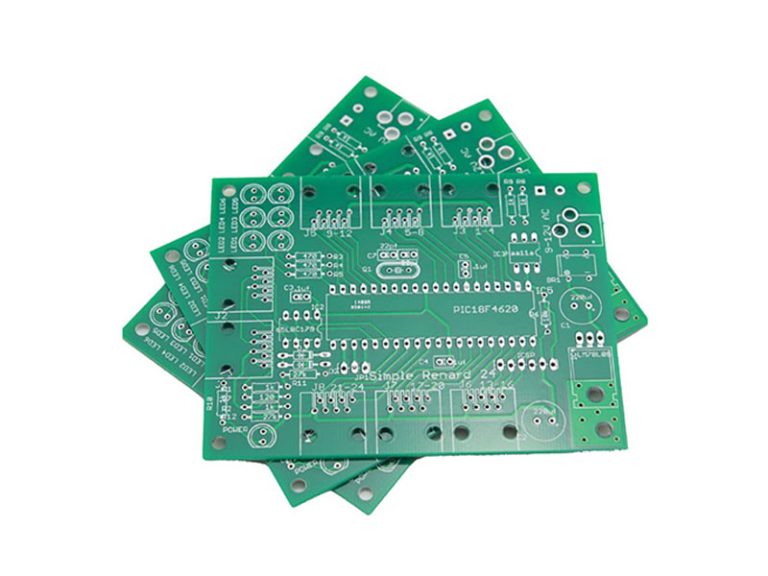

Single panel

The parts are concentrated on one side of the printed circuit board, while the wires are concentrated on the other. This type of printed circuit board is known as a single-sided board because the wires only appear on one side. Because single-sided circuit boards impose many restrictions on circuit design (due to the fact that there is only one side, wiring cannot cross and must be routed around a separate path), they were commonly used in early circuits.

Double panel

Wiring is present on both sides of this type of circuit board. A proper circuit connection between the two sides is required to connect the wires on both sides. A via is a type of circuit connection that connects two circuits. A via is a small hole on a printed circuit board that can be connected with wires on both sides and is filled with or coated with metal. The double-sided board can be used in more complicated circuits than the single-sided board because the area is twice as large as the single-sided board and the wiring can be interleaved (wound to the other side).

A printed circuit board must contain a large number of both passive and active components. Traces on the board connect the components from one side to the other. With the availability of very small-sized electronic components, it is absolutely possible to develop very large circuits on small printed circuit boards. To learn more about the printed circuit board, let us first examine its benefits and drawbacks.

Advantages of PCB by PCB board manufacturers.

- PCBs are inexpensive, and mass production can be accomplished at a lower cost.

- It is Re-workable.

- Widely available.

- Excellent shelf life.

- This board gives low electronics noise.

- Compact size and saving of wire.

- Because PCBs minimize the possibility of inaccuracy, inspection time is decreased.

- When compared to the traditional way, this board takes less time to assemble a circuit.

- This design contains no loose connections or short circuits.

- It is quite simple to verify and replace the specific failing components if there is any damage.

- Electrical qualities must be consistent from assembly to assembly on printed circuit boards.

- The location of the electronic component is permanent, making component identification and equipment maintenance a breeze.

- Component wiring and assembly both can be mechanized in a PCB board manufacturing facility.

All of the following variables contribute to the circuit’s performance being reliable. Disadvantages of PCB by PCB board Manufacturers.

- Uneven PCB surfaces finish.

- Not good for fine-pitch.

- It contains lead.

- Thermal shock.

- Solder bridging.

- Not easy to repair once damaged.

- It can be employed in a certain circuit.

- Once printed, we can’t be changed.

- Reduced or plugged.

- One sort of circuit operation necessitates reworking.

- The etching process used by PCB board manufacturers generates chemicals which are a harmful effect on the environment.

-768x513.jpg)

-768x576.jpg)