PCBA Assembly Service

Home > PCB Assembly Service

Why Choose Us?

Quick Response

Our production lines are highly efficient, ensuring timely delivery of orders.

Quality Assurance

Our strict quality control process and experienced team ensure that every PCBA meets the highest standards.

Price Advantage

We have a complete supply chain system and strict process system to provide customers with competitive prices

Technical Support

Our engineers and R&D team can provide you with comprehensive technical support to ensure the smooth completion of your project.

Our Production Capacity

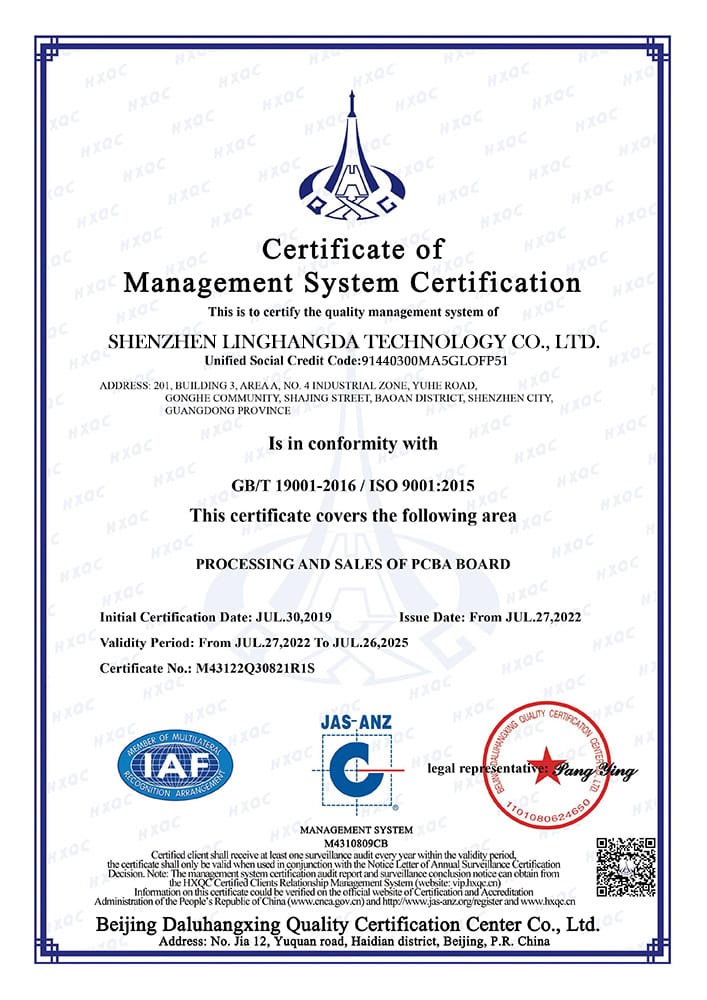

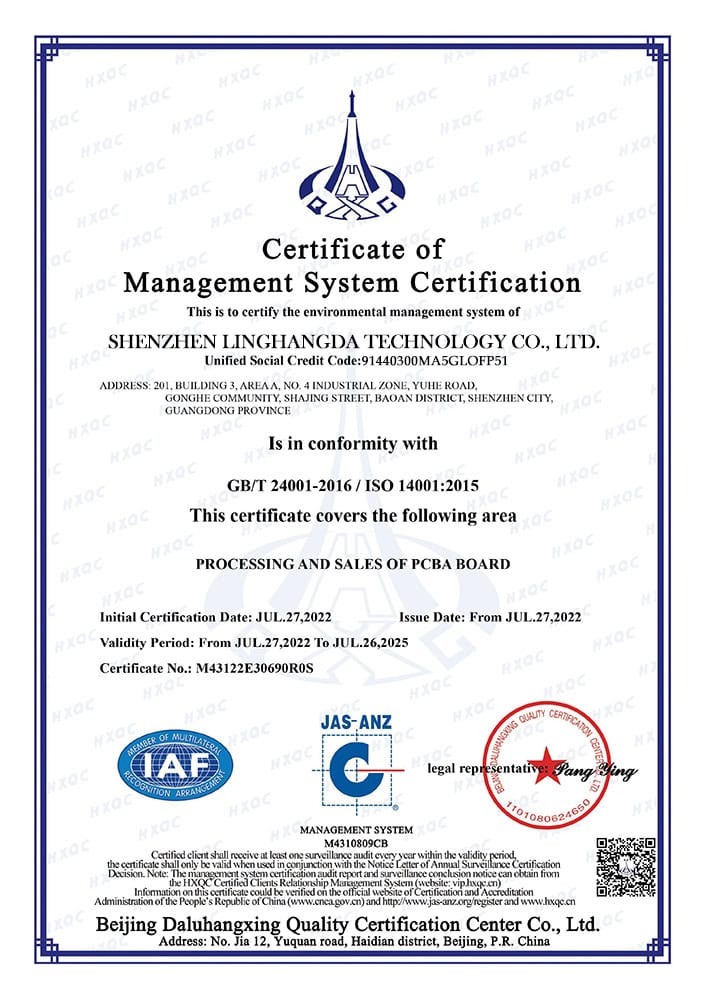

We are equipped with 7 industry-advanced production lines, able to quickly meet various SMT and DIP needs. From simple single panels to complex multi-layer boards, we can produce them efficiently. In addition, our factory is ISO14001 and ISO9001 certified, ensuring that every PCBA meets strict quality standards.

Technology and Applications

Printed Circuit Board Assembly

Printed Circuit Board(PCBs)is an very important part of electronic equipment in nowaday’s life, Printed Circuit Board Assembly is a very critical process for solder electronic components on PCBs. With the development of the technology, Printed Circuit Board Assembly technology are developing and progressing rapidly. It provide more efficient and reliable solutions for all fields.

The Importance of PCB Assembly

Printed Circuit Board Assembly is to mount different types of components (such as resistors, capacitors, integrated, etc) on PCB as per the designer’s design. To achieve the different functions of electronic products. Good assembly quality will affect the function, reliability, and stability of electronic devices.

PCB Assembly Process

Surface Mount Technology (SMT)

Surface Mount Technology(SMT) is the mainstream PCB technology. It solders electronic components on the PCB surface directly and sticks them to the PCB through welding. It has high advantages such as fast assembly speed, high circuit density, and strong anti-interference ability, and is suitable for the manufacturing of most electronic products.

Welding Process

Welding is the key process in Printed Circuit Board Assembly, it mainly includes wave soldering, reflow soldering, and manual soldering. Different welding processes are suitable for different types of electronic components and PCB boards. To ensure the welding quality can keep the electronic deceive/products stable.

our service

SMT Assembly: Our SMT production line uses state-of-the-art technology to ensure high efficiency and precision.

DIP Plug-ins: We provide professional DIP Plug-in services to meet your special needs.

Reverse Engineering: Our team of engineers can help you with reverse engineering and provide technical support for your project.

Purchasing components: We work with reliable suppliers to ensure the quality and supply of required components.

PCBA design: Our R&D team can provide customized PCBA design services according to your needs.

24/7 After-Sales Service: We provide 24/7 after-sales support to ensure your project runs smoothly.

PCBA Production Process

Future development trends of PCB assembly

With the electronic products development, and the trend of miniaturization intensifies, PCB assembly technology will take the following development soon

High-Precision Integration

The integration of components on the PCB will improved, to achieve smaller sizes and higher-performance devices and products.

Artificial Intelligence

Add artificial intelligence, machine study, and technology, to improve the PCB assembly efficiency and quality control level.

Environment energy saving

Use environmental technology and materials, to reduce the impact on the environment.

We should continue to improve the PCB Assembly technology and application, improve our understanding, and study more techniques when we pursue technological innovation. To provide more and more reliable and efficient support for the development of electronic products.