Table of Contents

ToggleWires and cables are vital in commercial, industrial, and residential applications. They facilitate data and power transmission in/ between connected equipment, devices, and systems.

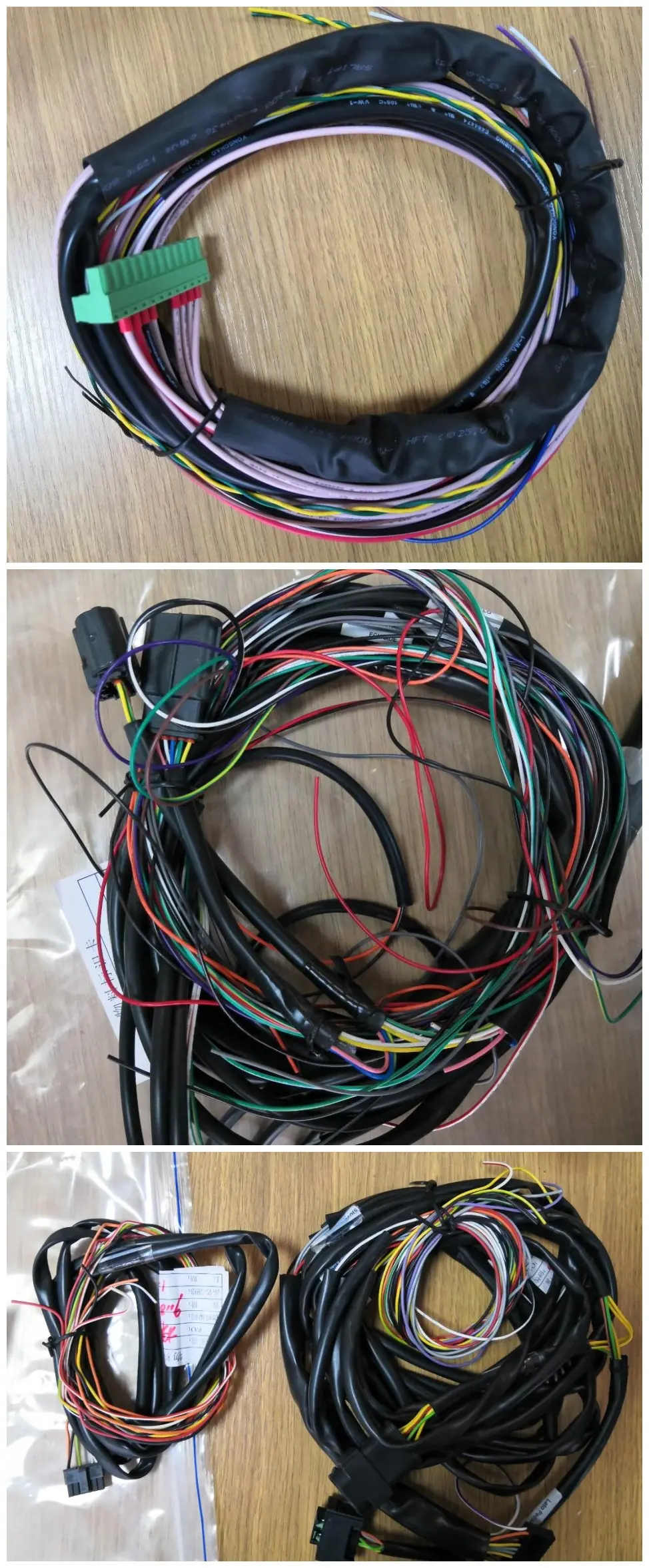

With its numerous applications, custom cable manufacturers have designed various standard variations, each offering unique characteristics, making them suitable for multiple uses. Other customers have highly specific requirements that are why it’s necessary to rely on experienced custom cable manufacturers.

There are various reasons why you should choose custom cables over standard cables. It includes:

Durability

Custom cables are tailored to current, voltage, and other operating parameters designed specifically for the intended use. Custom cables are equipped with the necessary characteristics to offer a reliable performance longer than standard cables.

Versatility

Thanks to technological advancements, you can design a custom cable according to your envision. Most custom cable Manufacturers have adapted this technology as it has helped to do away with working around standard cables limitations.

Enhanced performance

By investing in custom cables, you get to design your product and manufacture connections that meet your needs. As a result, the custom cable is likely to be effective and efficient, leading to lower energy use and better transmission.

Key Design Elements for Consideration

Once you decide to invest in custom cables, manufacturers will help you with the design process. Here are the essential design elements for consideration.

Cable type

Cables range from small consumer electronics to large-scale industrial systems. It is necessary to select one that meets your specific needs. The custom cable should offer various conductor options: multi-conductor, single conductor, multi paired conductors, and much more to help you select according to your needs.

Operating temperature

Temperature plays a major role in a cable’s performance, especially the strength and stability of the ampacity and insulation of the cable. So, when designing a custom cable, you should always have operating temperature in mind.

Electrical properties

The capacitance, ampacity, and voltage needed for a custom cable vary depending on the application. You can modify each parameter to ensure your system performs optimally.

- Capacitance. It is the amount of charge that a conductor stores.

- Voltage Rating. It’s the maximum voltage in which a cable gets connected and also complies with the applicable regulations.

- Ampacity. It’s the maximum current that a cable can carry without exceeding operating temperatures.

Flexibility

This feature depends on the application of the cable. Solid conductors are best for cables that require greater rigidity. On the other hand, multi-stranded conductors are suitable for cables that need greater flexibility.

Usage

The custom cable can be for either indoor or outdoor use. Cables for indoor use have a different requirement than those of outdoor environment. The cable needs sufficient protection for outdoor use because they get exposed to elements and harsh environments.

Industry standards

All cables must comply with industry regulations as a guarantee safety of end-users. Check out some of the most relevant standards to consider, such as UL, CSA, and NEC.

Why Custom Cable Manufacturers?

The type of cable you select has a great impact on the performance of electronic products. To avoid inconveniences, it’s crucial to partner with professionals and experienced custom cable manufacturers to receive high-quality products that meet your needs and standards.

LED Technology is a leading custom cable manufacturer for thousands of custom contract cables. We monitor all of our product inspection procedures. Shipping is approved if there is no manufacturing failure.

For all your custom cable needs, call LHD Technology today.