One Stop Service

Home > One Stop Service

LHD PCB provide one-stop service

we can do PCB design , PCB&PCBA production and assembly. It usually includes the following aspects:

01

Design and layout

We can design PCB layout and schematic circuit diagrams, and even optimize and simulate circuit design.

03

PCB Production

This includes a series of manufacturing processes such as how to choose board material, etching , drilling, and surface treatment of PCB.

05

PCB Assembly

Soldering components onto a PCB, including surface mount technology (SMT) and through-hole technology (THT).

07

Finished Product Assembly

We also have extensive experience in providing final device assembly services for PCBs that need to be further assembled into larger systems or devices.

02

Prototype

Prototyping is an important step to verify that the design if meets functional and performance requirements before bulk production.

04

Component Sourcing

We can purchase all the components the PCB requires, which usually includes active and passive components.

06

Fuctional Testing and Quality Control

After completing the assembly, the PCB board needs to be subjected to functional testing, visual inspection, and possibly other quality control processes to ensure that the PCBA meets the normal standards.

08

Logistics and After-sales Support

After the production is completed, we will also be responsible for the safe delivery of the products to the customer, and provide necessary after-sales support, such as technical consultation and product maintenance.

IC Decryption

Cable Assembly & Box Building

Cable Assembly & Box Building

Firmware Design

LHD PCB design one-stop service finally provides customers with the following contents:

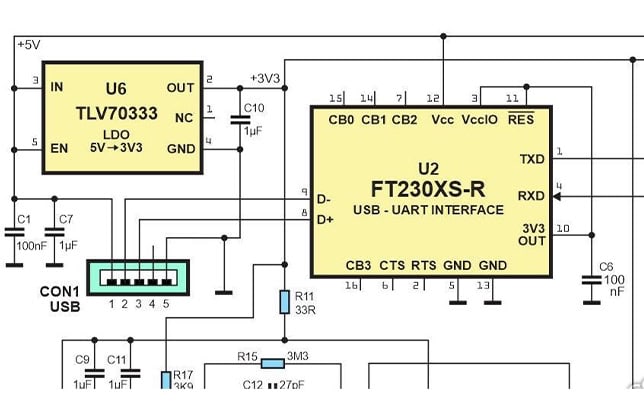

SCH Schematic Files

PCB schematic is one of the important steps in circuit board PCB design. A PCB schematic is a graphical representation of the connections between the components of a circuit. In a PCB schematic, the circuit diagram elements, wires, and pins of the device are connected by symbols and wires to form a complete circuit diagram, which is the core of the PCB schematic

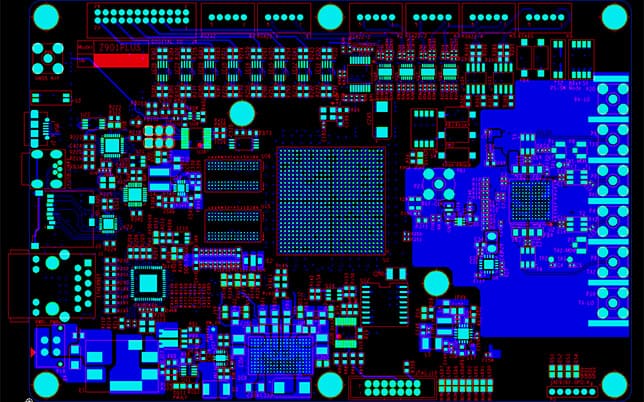

PCB Design File (PCB diagram or Gerber file)

PCB design files are the documents used in the design and manufacture of PCB, and they contain all the information needed to manufacture a PCB. These files are used to detail the layout of the board, component placement, trace routing, layer stacking, hole locations, and other information.

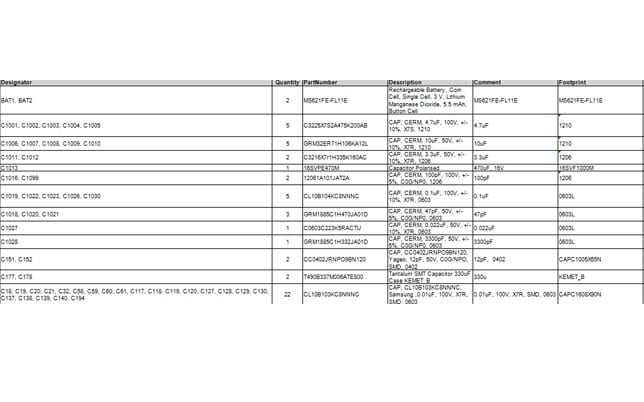

BOM

BOM is a list of all the parts required to manufacture a particular PCB during the manufacturing process. It usually contains designator, descriptions, quantities, manufacturer names, manufacturer part numbers, supplier information, and any special requirements or other important information.

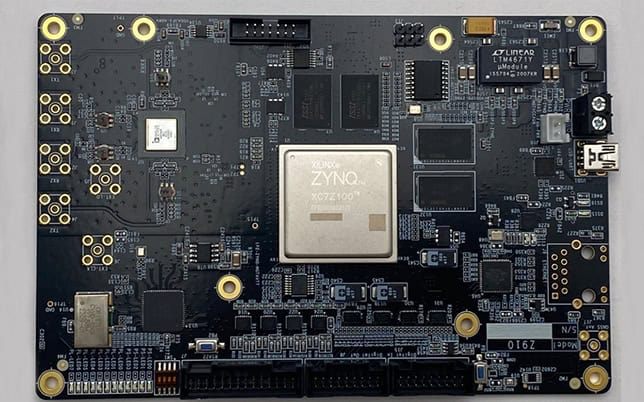

PCBA Sample

After the design is completed, we will assemble a PCBA sample for you to test and verify the correctness, functionality and performance of the board design.

What is One-Stop Service of PCBA

One Stop also known as “Turnkey” PCB/PCBA service is a complete solution, include DFM Checking, PCB Fabrication, Electrical Testing, Parts Procurement, PCB Assembly, Automated Optical Inspection(AOI)

Cost

Raw material cost from PCB, components cost, assembly cost, package cost, especially the transportation cost, all the cost are within our control. We will also recommend you the most favorable and fastest mode of transportation for you to choose.

Oversight

We will send WIP every day so that you can see the progress of the project more clearly. There will be a specified person to follow up on each of the projects. This process of one-stop PCB service also simplifies the on-site audit process, sometimes as an option that would otherwise be too costly or demanding.

Delivery time/Lead time

Turnkey PCB services can often reduce lead times simply because communication is easier, but this is certainly not the only reason for reducing lead times for one-stop PCB services. We always ensure that part procurement occurs simultaneously with PCB manufacturing and that all parts arrive at our production facility before the bare PCB is completed.

Quality

Each of our incoming links will have professional quality personnel for quality testing. We will assign a project for your order who will continue throughout the production process.

Service

We provide an online order tracking system for all customers, which will be updated daily according to the status of your ongoing project. If you have any other questions, you can contact our responsible personnel at any time.

Why Choose LHD PCB

We design fast, high accuracy amd charge a reasonable price.

We design fast, with high accuracy, and charge a reasonable price.

In general, 1L and 2L designs are completed within 1 day, 4L design is completed within 2 days, and 6L to 10L designs are completed within 3 days, and the specific PCB design cycle depends on specific requirements.

We have rich experience in PCB design

Our products have been successfully designed to cover today's mainstream electronic product fields: communications, IOT, industrial control, automotive electronics, aerospace, scientific research, medical, consumer electronics and others. In particular, he has rich experience in simulation and PCB design in the fields of high-frequency PCB, high-speed PCB, PCB signal integrity simulation analysis, digital-analog A/D mixed circuit board design, etc.

Total Quality Management

We not only pay attention to advanced technology, but also carry out quality management on the whole production process of PCB, including excellent product design, high-quality materials, suitable equipment, mature production technology, skilled production personnel, and strict and meticulous inspection, storage and packaging, etc.

Strong Overall Strength

We can provide a full set of services including PCB design, prototype debugging, component procurement, high-precision board making, SMT chip processing, etc., and can design the products required by customers according to customer requirements, including secondary development of functional improvement and technical optimization of existing products.

Perfect Post-service System

External: Adhere to the service tenet of "customer first" and solve problems for you. If necessary, the technical person will come to provide technical services to ensure that the user's product can be used normally and effectively maintain a certain contact with the customer, and pay attention to the use of the product.

Internal: Accurate and timely feedback on the use of products, quality information, and various important social information, so that enterprises can make correct decisions promptly and better serve our customers.