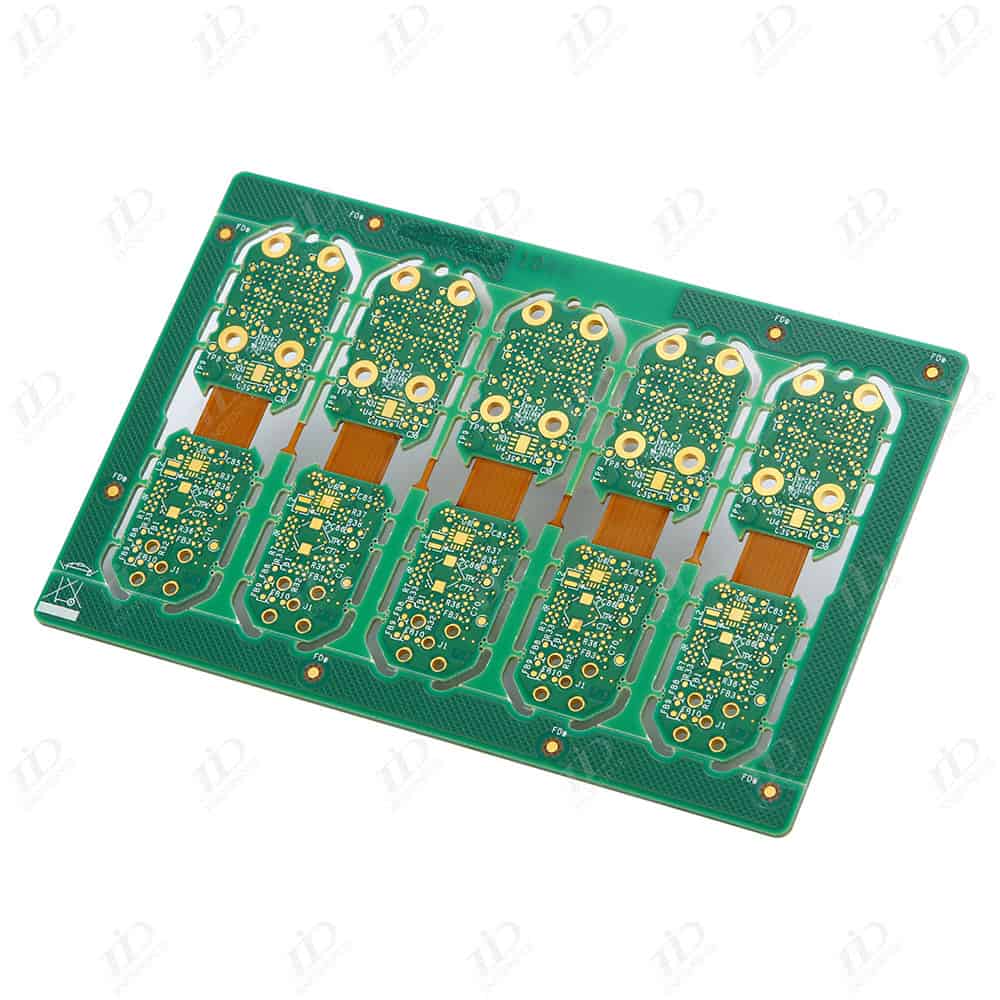

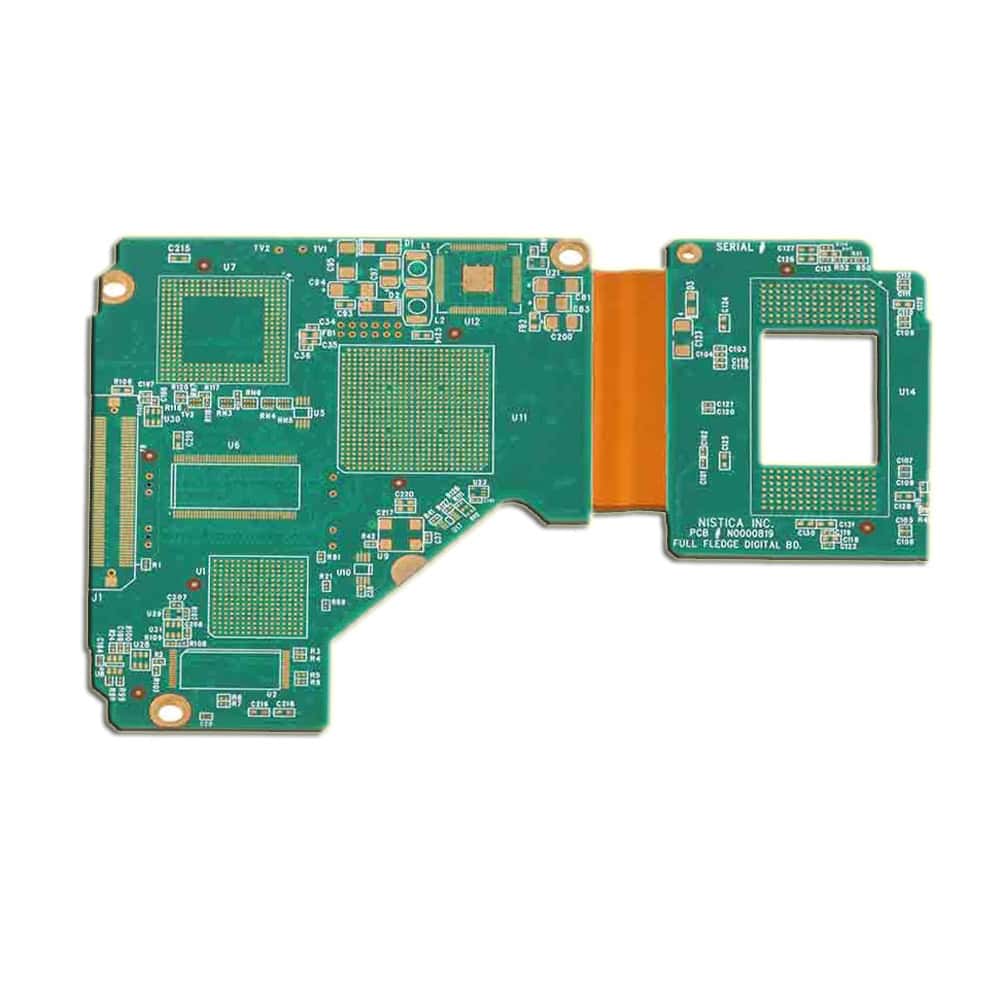

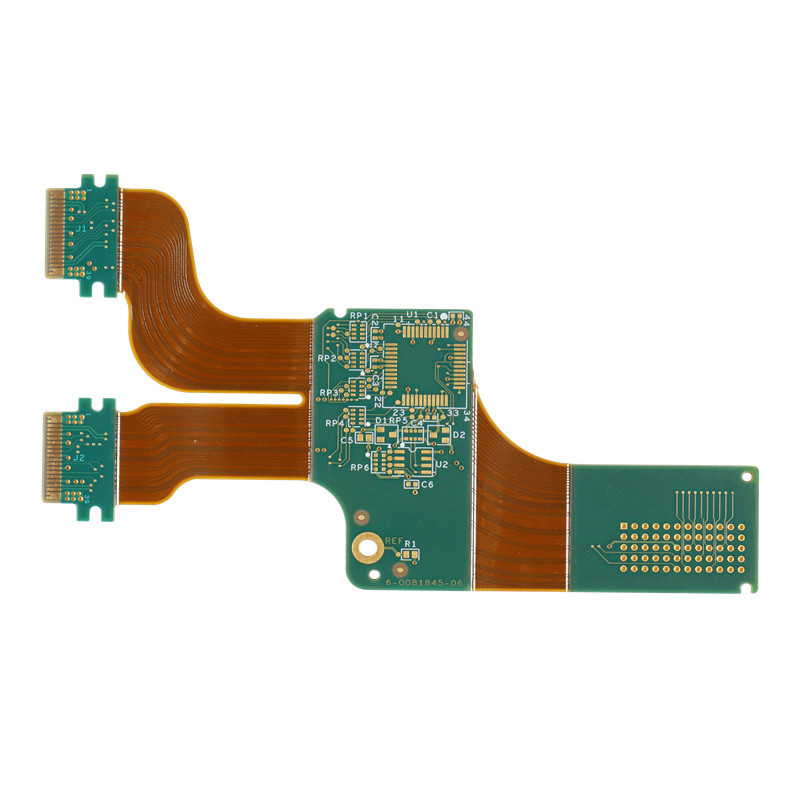

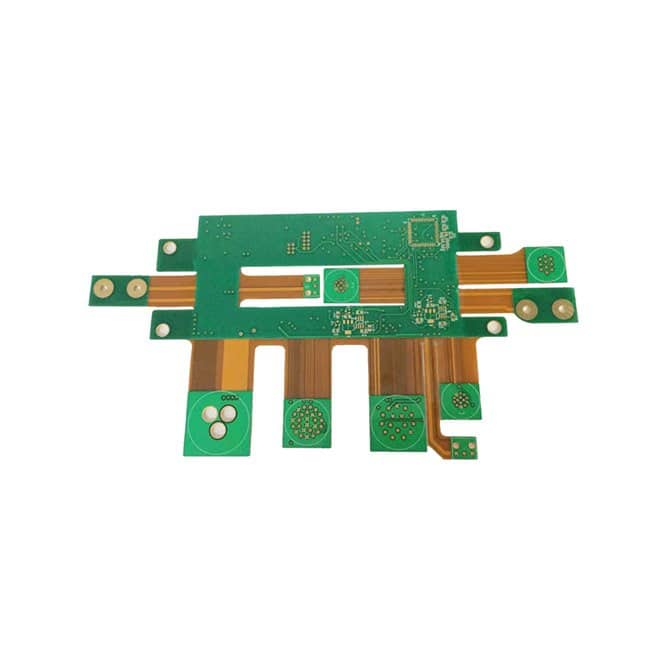

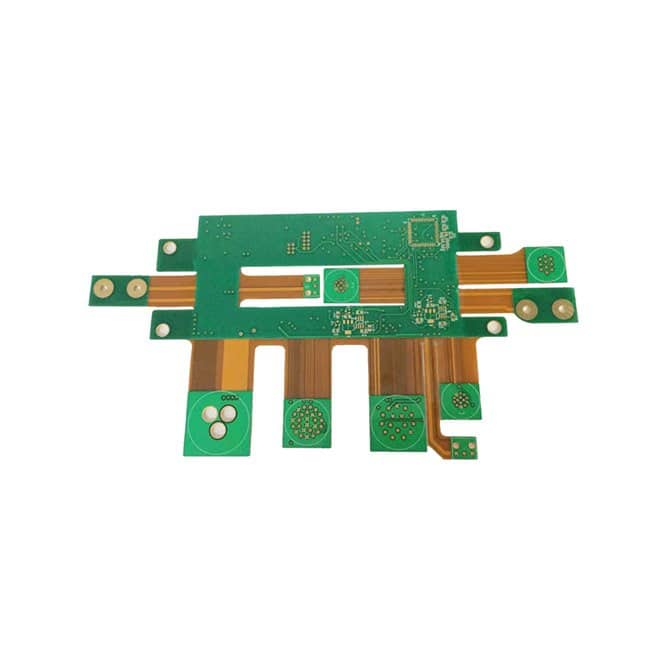

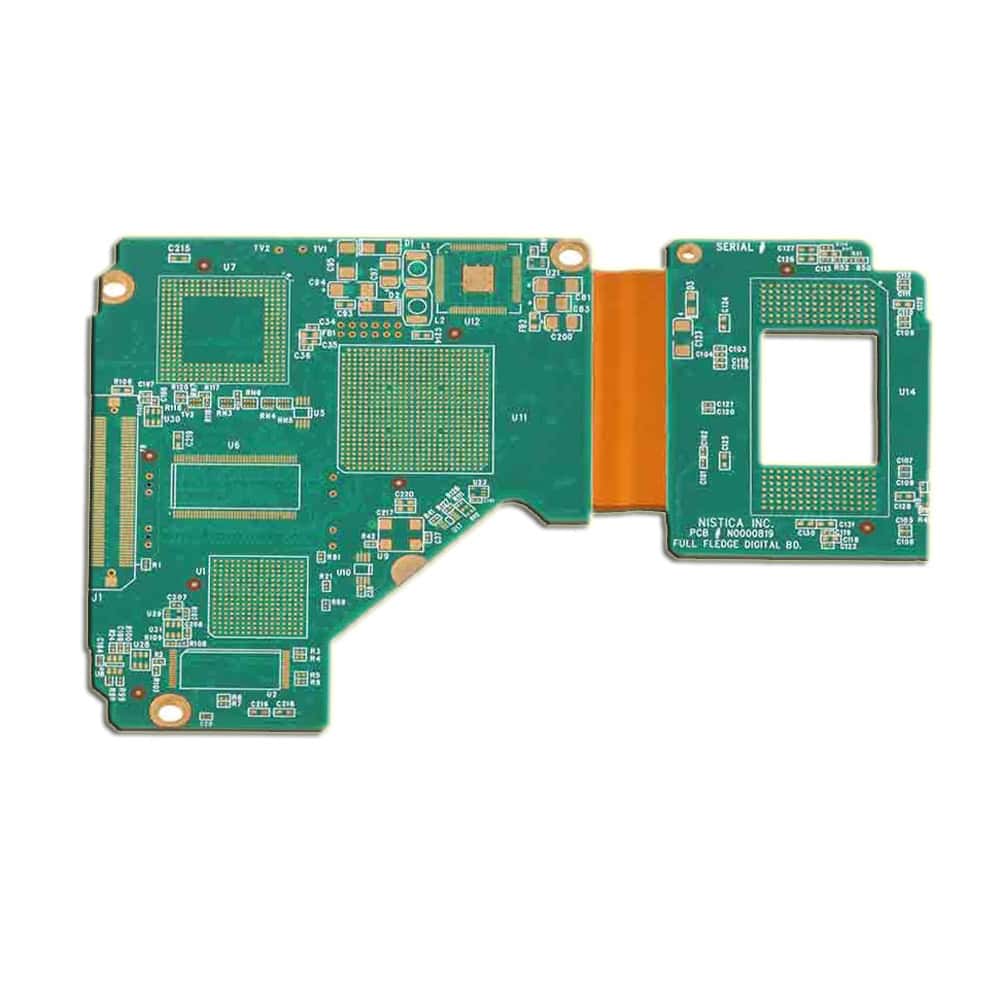

Rigid-Flex PCB

What Are You Struggling With?

Eu orci sed nulla mattis id fermentum rhoncus enim eleifend ultricies erat libero eu aliquam mauris vitae magna elementum egestas.

Space Optimization

Reduced connectors and cables

Enhanced reliability&durability

Design Flexibility

What is a hard and soft board?

The soft and hard bonding plate refers to a copper-clad plate formed by bonding with copper foil on one or both sides of flexible insulating materials such as polyimide film or polyester film through a certain process. That is, flexible circuit board and hard circuit board, after pressing and other processes, according to the relevant process requirements combined together to form a circuit board with FPC characteristics and PCB characteristics.

The material of the soft and hard bonded plate is a flexible copper clad plate composed of three different materials, namely copper foil, film and adhesive, which is called a three-layer flexible copper clad plate (referred to as “3L-FCCL”). The adhesive free flexible copper clad plate is called two-layer flexible copper clad plate (” 2L-FCCL “).

FCCL is composed of three main categories of materials:

Insulating base film materials

The most widely used are and polyimide film (PI film) and polyester film (PET film).

Metal conductor foil

commonly used copper foil, aluminum foil and copper-beryllium alloy foil. Most of them are copper foil, including electrolytic copper foil (ED) and calendered copper foil (RA).

Adhesives

polyester adhesives, acrylic adhesives, epoxy or modified epoxy adhesives, polyimide adhesives, phenolic butyraldehyde adhesives, etc. Adhesives in 3L-FCCL are mainly divided into two schools: acrylic adhesives and epoxy adhesives.

Soft and hard combined board advantages

1, it has the advantages of flexible plate and rigid plate support;

2, the finished product is small in size, light in weight, can meet the three-dimensional assembly requirements, meet the needs of consumer electronic products, and has a huge market potential;

3, the combination of soft and hard structure can greatly reduce wiring and connectors, giving the designer greater design freedom;

4, low installation cost;

5, suitable for folding structure;

6, Reliability of the product.

The processing flow of soft and hard combined board

Blanking → pre-drying → inner pattern transfer → inner pattern etching →AOI inspection → Laminating inner line overlay → punching locating holes → multilayer laminating → drilling through holes → plasma dedrilling → Metalizing holes → Electroplating → Outer pattern transfer → Etching outer pattern →AOI inspection → Laminating outer layer overlay or coating protective layer → Surface coating → Electrical performance test → Contour machining → inspection → Packaging

Reasons to choose LHD for Rigid-flex PCB

we have rich experience in the design and manufacture of rigid-flex PCBs.

Professional Experience

Provide customized solutions according to customer's specific needs.

Customized Service

Using the latest technology and high quality materials to ensure the performance and reliability of our products.

Advanced Technology

Strict quality control at every stage from design to production to ensure products meet high standards.

Strict Quality Control

Rigid-flex PCB Capability Overview

| Number of layers | 1-6 |

|---|---|

| Finished board thickness (thinnest) | 3 mil (0.08mm) |

| Minimum Hole Diameter | 4 mil (0.10mm) |

| Minimum line width/spacing | 2 mil (0.05mm) |

| Maximum Board Size | 10" x 45" (250x 1200mm ) |

| Surface Finish | OSP, tin spray, electro-nickel/gold, electroless nickel/gold, lead-free tin spray, immersion gold. |

| Insulation resistance | ±1011Ω (Normal Normal) |

| Thermal shock resistance | 260 ℃ 10 seconds |

| Processing materials | polyimide ( PI ), polyester ( PET ), polyimide ( PI ) + FR4 |

Related Products