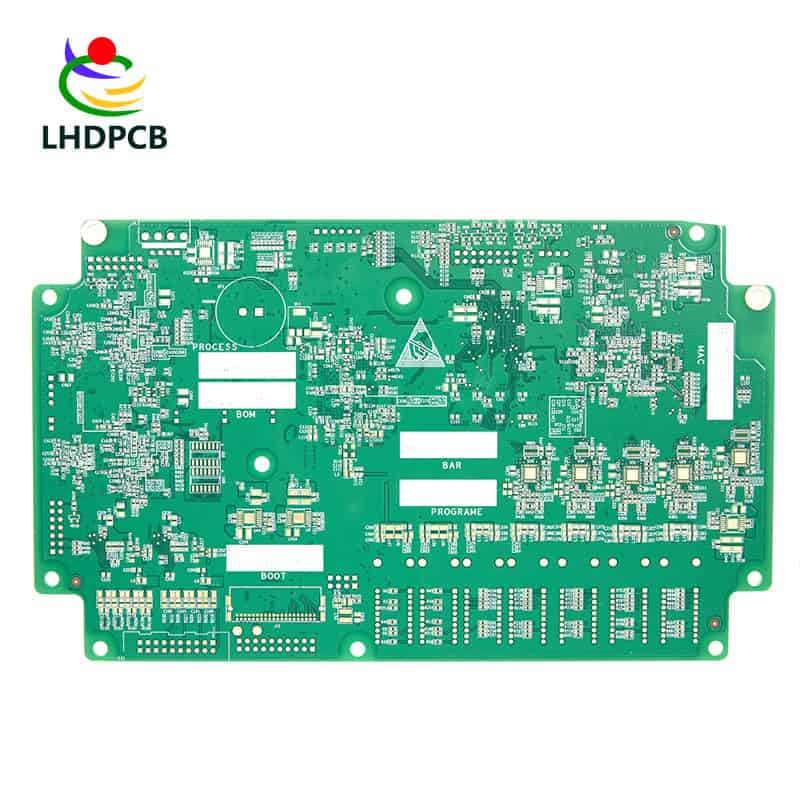

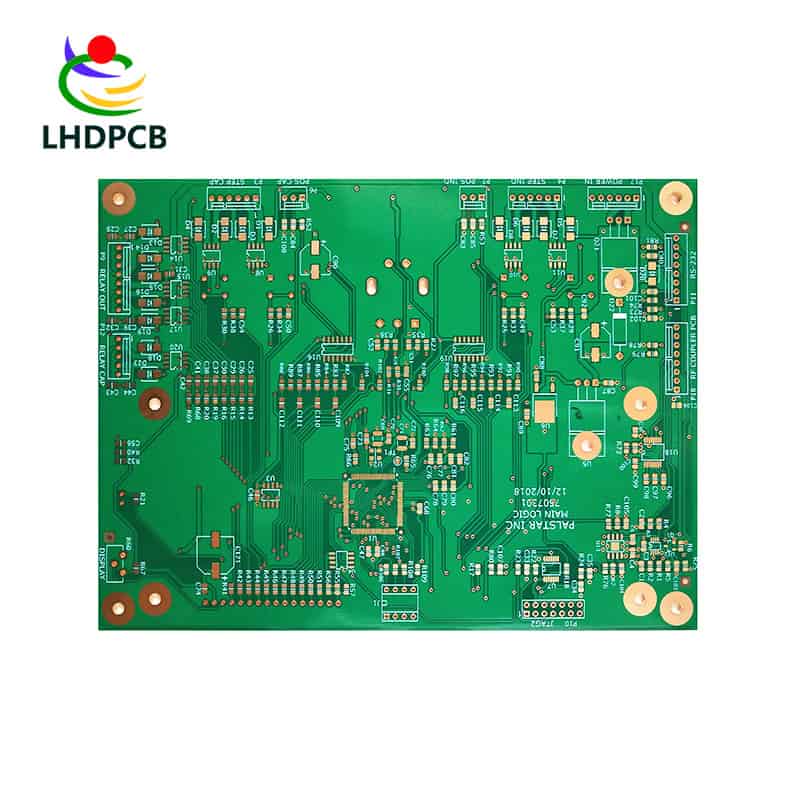

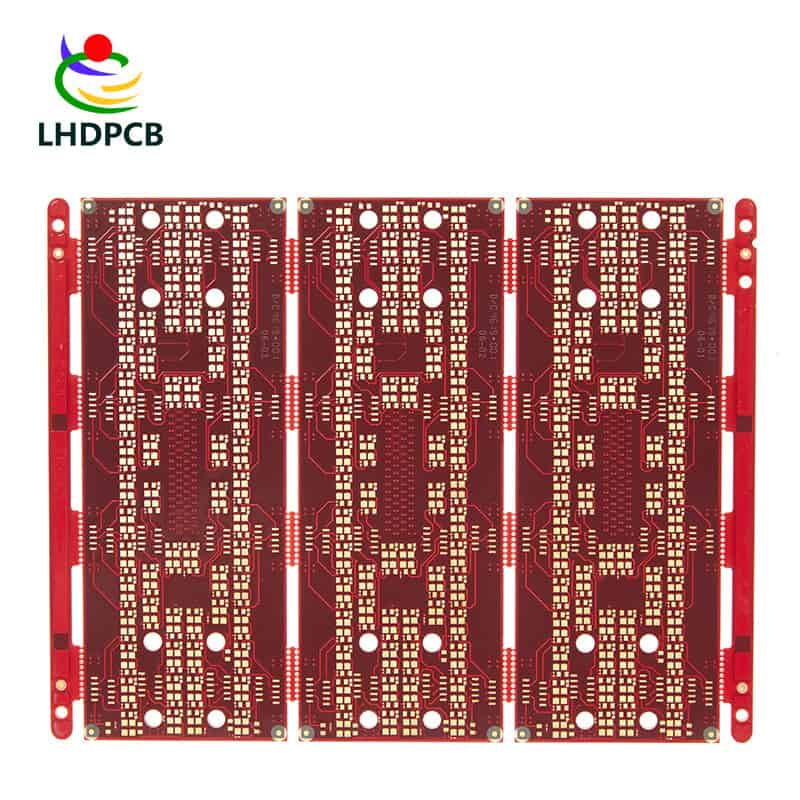

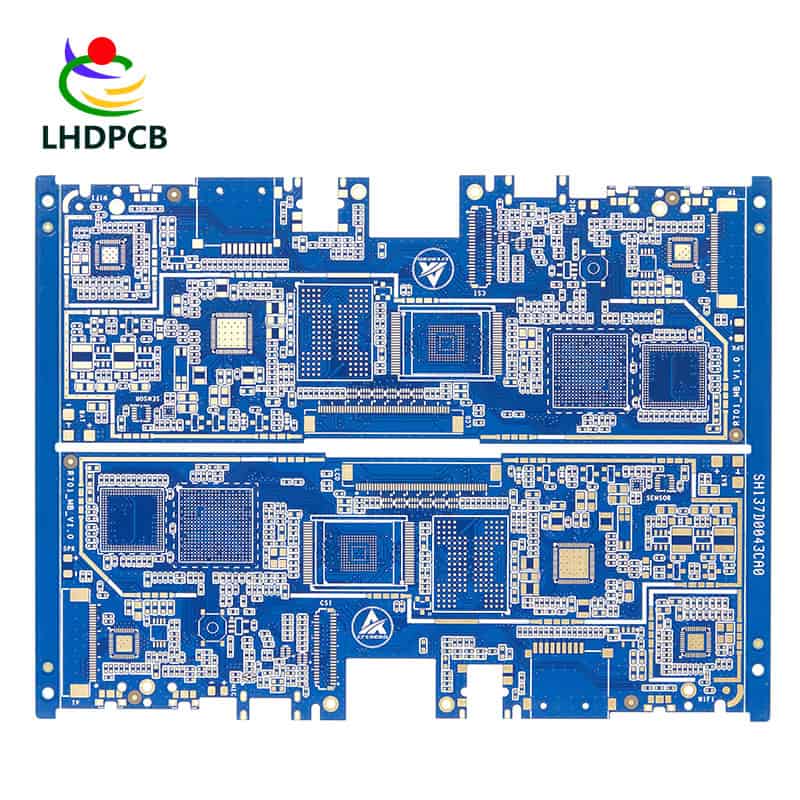

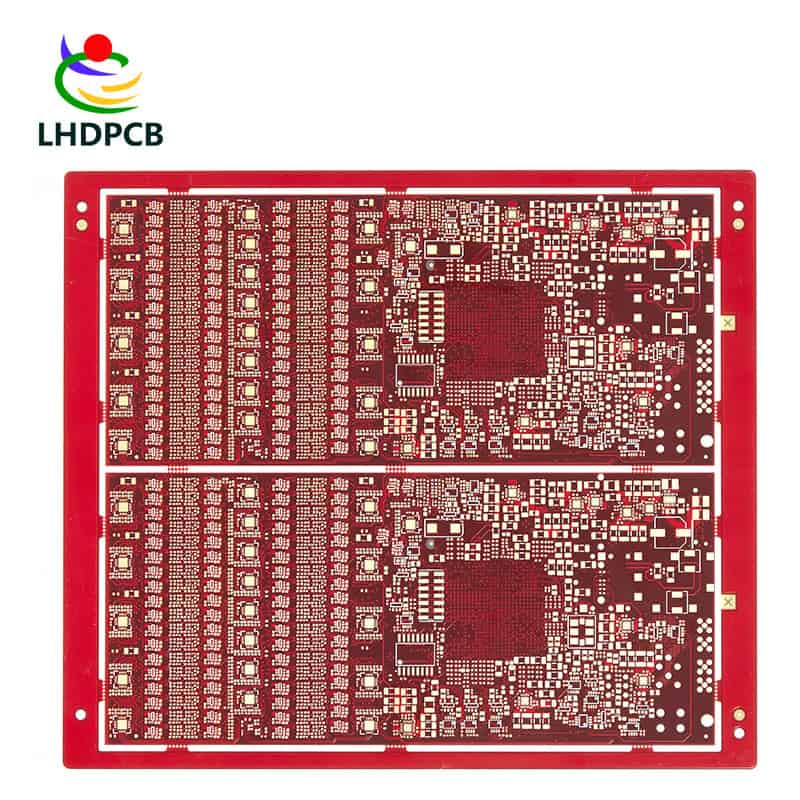

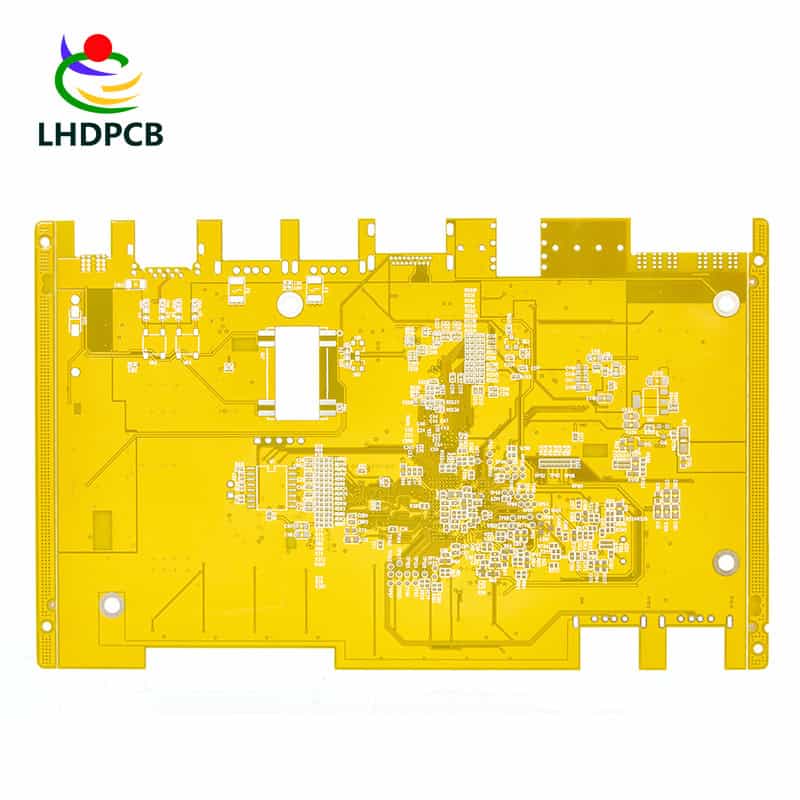

FR-4 PCB

What is FR-4 PCB?

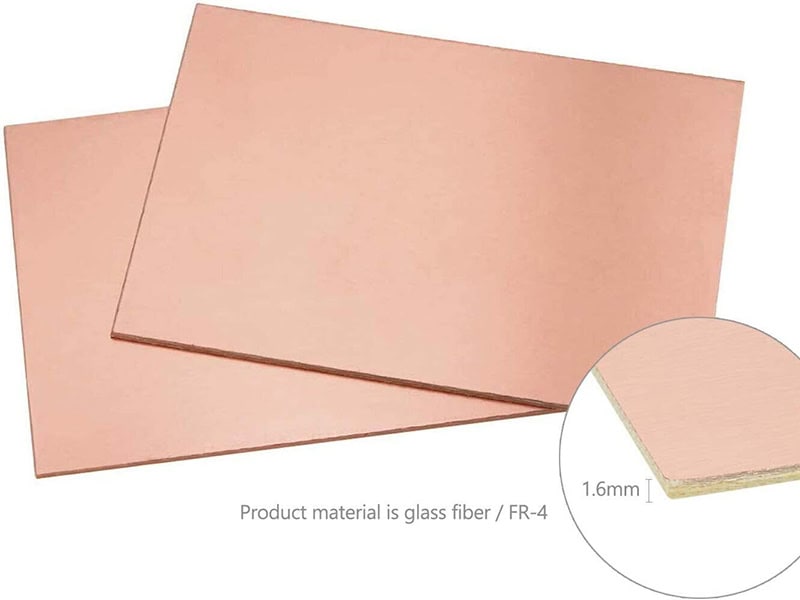

FR-4 PCB is a type of printed circuit board widely used in the electronics industry. FR-4 refers to Flame Retardant (Flame Retardant) Class 4 material, which consists of glass fibers and epoxy resin, and is considered to be the standard substrate material in circuit board manufacturing.

FR-4 material is made of glass fiber cloth and epoxy resin composite, with high strength, high rigidity and flame retardant. Among them, the glass fiber cloth is responsible for enhancing the mechanical strength and stability of the circuit board, and the epoxy resin provides good insulation properties and high temperature resistance. Its strength, stability and supply chain maturity make it one of the most widely used materials in PCB manufacturing.

The most obvious difference between FR-4 materials is the Tg value, according to the Tg temperature, FR-4 plates are generally divided into low Tg, medium Tg and high Tg plates.In the industry, FR-4 Tg of about 135℃ is usually classified as low Tg sheet; The FR-4 of Tg at about 150℃ is medium Tg plate; FR-4 Tg at about 170℃ is classified as high Tg plate.If the PCB is processed with more times of pressing, or more PCB layers (more than 14 layers), or the welding temperature is high (≥230 ° C), or the working temperature is high (more than 100 ° C), or the welding thermal stress is large (such as wave welding), high Tg plate should be selected.

Why Choose LHD Tech

Quality Assurance

Our strict quality control systems and advanced manufacturing equipment ensure each FR-4 PCB meets high-quality standards, ensuring stable and reliable product performance.

Innovation and Customization

We stay at the forefront of PCB manufacturing technology, offering customized solutions to meet specific requirements. Whether it's complex multi-layer designs or specialized surface treatments, we provide expert support.

Cost-Effectiveness

By optimizing production processes and employing automated equipment, we offer competitively priced FR-4 PCB without compromising quality, helping clients reduce production costs and enhance market competitiveness.

Timely Delivery

We prioritize production efficiency and delivery times, ensuring fast turnaround times even for large orders or complex custom requests, and meeting urgent market demands.

LHD Technology FR-4 Production Capacity

| Processing layers | 1-48 layers |

|---|---|

| Finished board thickness (thinnest - thickest) | 0.008″ ~ 0.24″ (0.20mm ~ 6.0mm) |

| Minimum Hole Diameter | 6mil (0.15mm) |

| Minimum line width/spacing | 3-4 mil (0.076-0.10mm) |

| Maximum board size | Single and double layer 22″x 43″ (550 x 1100mm) Multilayer 22″x 25″ (550mm x 640mm) |

| Impedance control | ± 10% |

| Surface treatment process | oxidation resistant OSP, tin spraying, electric nickel/gold, chemical nickel/gold, lead-free tin spraying, gold finger, immersion silver, immersion tin, thick nickel/gold. |

| Processing materials | FR4 (Sangyi, KB, International), high TG (TG150, TG170), halogen-free plates, high-frequency plates (Rogers, Teflon, Taconic), domestic PTFE (F4B, F4BK),, aluminum substrate (Berquist, domestic Al-based), copper-based, iron-based, ceramic substrate. |

Related Products