What is Surface Mount Technology?

SMT is a surface mounted technology, which is currently the most popular technology and process in the electronics assembly industry.

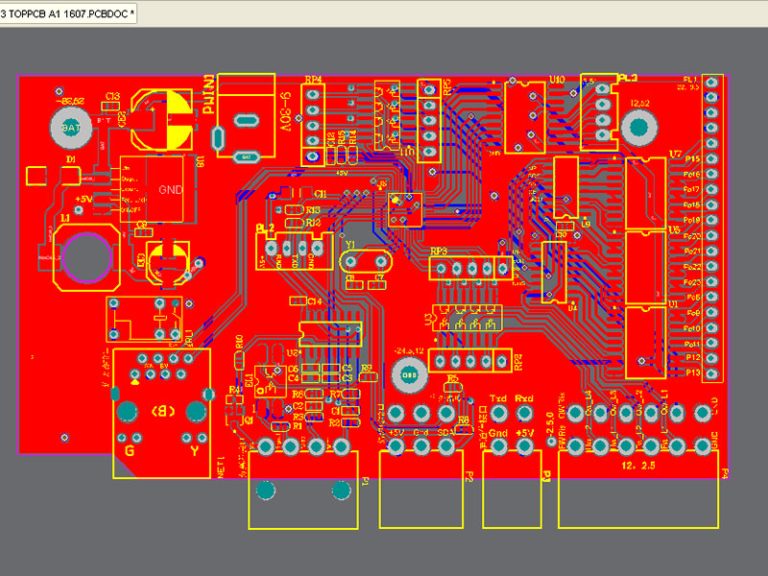

It is a kind of surface assembly components without leads or short leads (SMC/SMD for short, chip components in Chinese) mounted on the surface of a printed circuit board (PCB) or the surface of other substrates. Reflow soldering or dip soldering and other methods to solder and assemble circuit assembly technology.

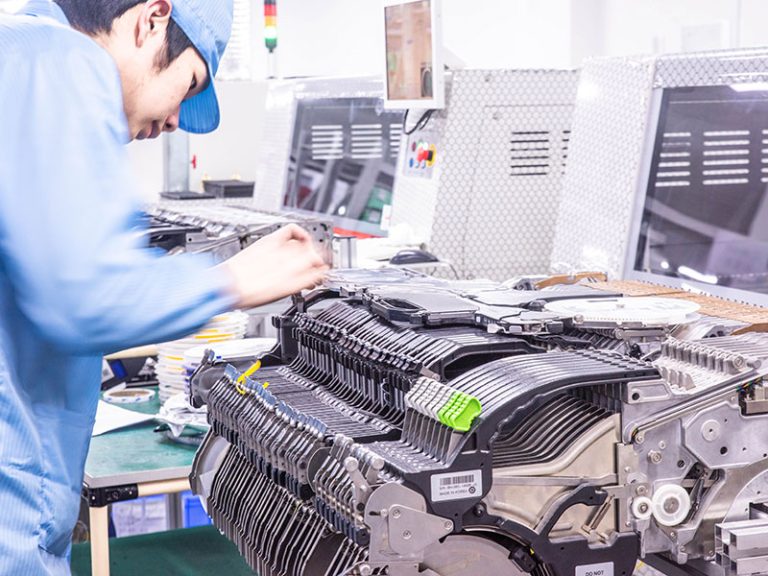

Process composition

Printing (red glue/solder paste) –> Inspection (optional AOI automatic or visual inspection) –> Mounting (first paste small devices and then paste large devices: divided into high-speed placement and integrated circuit placement) – >Inspection (optional AOI optical/visual inspection)–>Welding (using hot air reflow soldering for soldering)–> Inspection (can be divided into AOI optical inspection appearance and functional test inspection)–> Maintenance (tool: welding Table and hot-air desoldering station, etc.) –> board splitting (manual or splitting machine for cutting boards)

The process flow is simplified as: printing——-patch——-welding——-overhaul

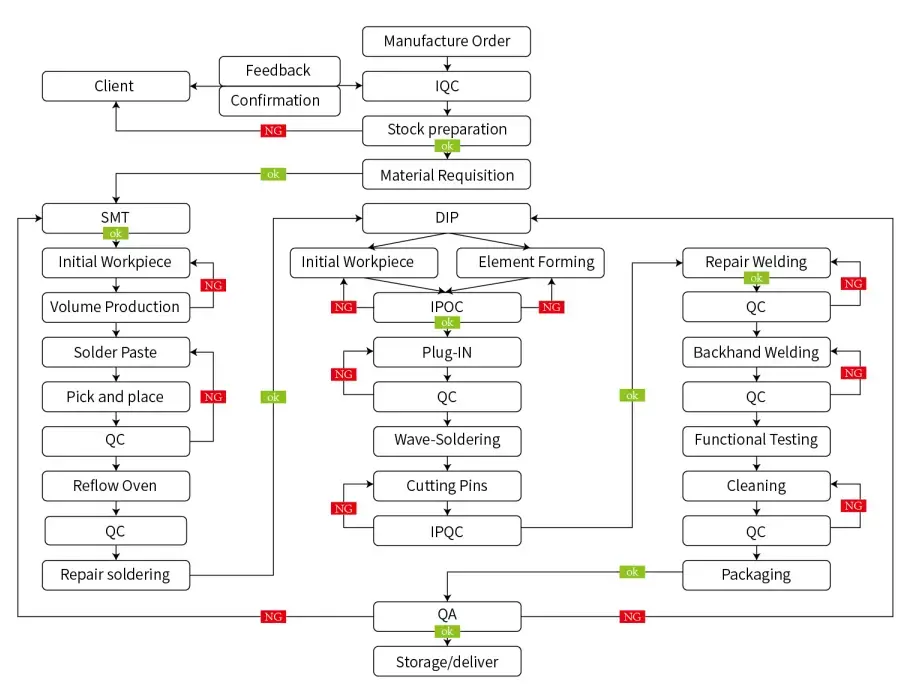

LHD Technology’s PCBA Quality Control Process

-768x513.jpg)

-768x576.jpg)