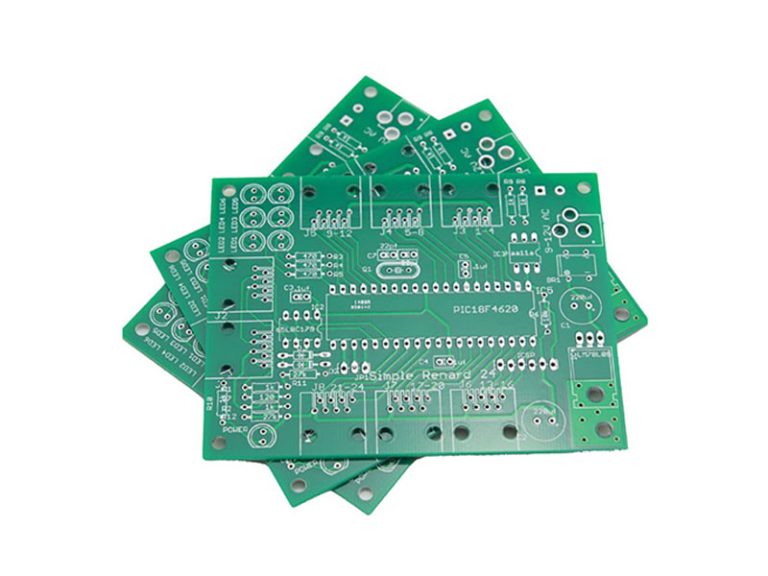

At LHD Technology every process have detailed and strict control plan. Regularly check and maintain all facilities.

Following IPC requirements, assuring 100% FQA rate. Running throughout PDCA flow, continuously improve quality peroformance. Performing lean production, establishing.

ERP systemn, to ensure effective and accurate management.

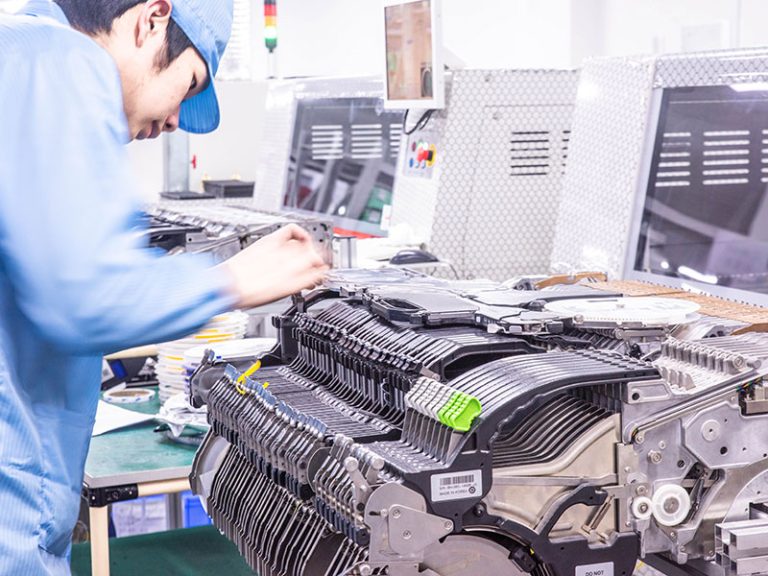

Close collaboration within process

Our strategy is to be on the spot and work directly and closely. Our Factory Supervisors are directly responsible for each process’s performance as well as for building relationships and acting proactively and reactively. The Logistics team follows purchase orders and deliveries from the factories on a daily basis and provides feedback to the factory. Our QA Team performs audits/mini-audits, working proactively on quality performance. We compile complaints and delivery statistics, and resolve problems through resolute action All process have been set clear targets through our KPIs (Key Performance Indicators).

Rapid problem solving and early warnings

A key element of factory management is rapid problem solving if and when deviations occur. Technicians and/or Quality Engineers can be on site at short notice in order to find the root problem and quickly resolve it. This also applies with regard to rapid implementation of specific customer requirements or issues relating to specific projects. In the event of delays, we can expedite a special delivery where needed. Frequent progress updates are shared with our customers. Our staff are responsible for each process and our aim is to have a presence at all our main process.

-768x576.jpg)